The Automatic Sheet Fed Paper Bag Machine is an innovative piece of machinery designed to automate the process of producing high-quality paper bags. With its ability to work with pre-cut sheets of paper, this machine offers significant advantages in terms of production speed, precision, and efficiency. It is widely used in industries that require packaging solutions, such as food, retail, pharmaceuticals, and consumer goods.

What is an Automatic Sheet Fed Paper Bag Machine?

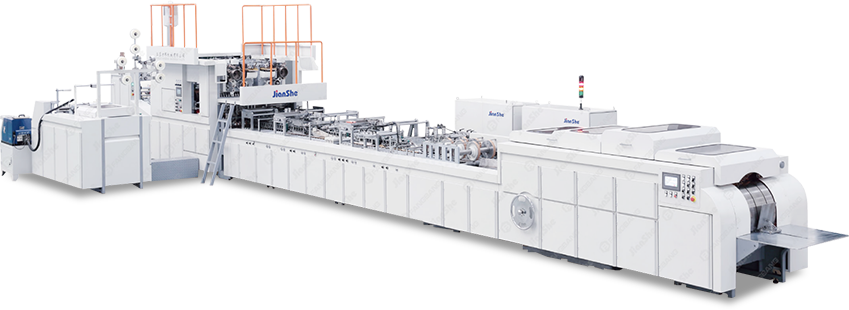

An Automatic Sheet Fed Paper Bag Machine is a fully automated system designed to create paper bags from pre-cut sheets of paper. It can handle various sizes and types of paper bags, including those with flat handles or twisted handles. The machine takes pre-printed or plain paper sheets, folds, glues, and seals them to form bags. Depending on the specific model, some machines also offer the option to print or emboss patterns and logos on the paper before bag production.

The machine’s automatic functions ensure that the process runs smoothly, producing bags at a rapid pace with minimal human intervention. This increases the overall efficiency of bag production, reduces labor costs, and improves the consistency and quality of the finished product.

Key Features of the Automatic Sheet Fed Paper Bag Machine

-

High-Speed Production

One of the standout features of an automatic sheet fed paper bag machine is its ability to produce paper bags at high speeds. These machines are capable of producing hundreds or even thousands of bags per hour, depending on the model. This high speed, combined with automation, helps manufacturers meet the growing demand for paper packaging in a cost-effective manner.

-

Precision and Consistency

The automated nature of the machine ensures high accuracy in every step of the bag-making process, from cutting the sheets to folding and gluing. This results in consistently high-quality bags with uniform dimensions, minimal defects, and a clean finish. The precision also allows for the creation of complex designs, ensuring that branding and logos are accurately printed on the bags.

-

Versatility in Bag Design

Automatic sheet fed paper bag machines are versatile and can produce a variety of bag styles. Common types include:

- Flat handle bags

- Twisted handle bags

- Bottom-sealed bags

- Side gusseted bags

This flexibility allows manufacturers to cater to a wide range of customer needs, from small retail packaging to large commercial packaging.

-

Sustainability

With growing concerns about environmental impact, paper bags are increasingly preferred over plastic bags for packaging. The automatic sheet fed paper bag machine contributes to sustainability efforts by efficiently producing eco-friendly paper bags. The use of recyclable paper, minimal waste, and energy-efficient operations make this machine a green choice for packaging.

-

Custom Printing and Embossing

Many models of the automatic sheet fed paper bag machine come with the option to add custom printing, embossing, or die-cutting features. This allows businesses to add their logos, branding, or product information to the bags, creating a personalized packaging solution that enhances their product appeal and visibility in the market.

Advantages of the Automatic Sheet Fed Paper Bag Machine

-

Higher Production Capacity: These machines drastically increase production rates by automating processes, allowing companies to produce a large volume of paper bags in a short time.

-

Reduced Labor Costs: By automating the paper bag production process, businesses can significantly reduce the need for manual labor, which cuts down on staffing costs and human error.

-

Improved Quality Control: Automated systems are precise, reducing the risk of defects. As a result, the final product is of consistently high quality with uniform sizes and finishes.

-

Customization Options: With integrated printing, embossing, and die-cutting options, businesses can create highly customized paper bags to match their brand or specific product needs.

Applications of the Automatic Sheet Fed Paper Bag Machine

-

Food Packaging

This machine is ideal for producing paper bags used in packaging food products like bread, pastries, snacks, and other consumer goods. The ability to print on the bags also makes it suitable for branding and marketing purposes.

-

Retail Packaging

Paper bags are commonly used by retailers to package products purchased by customers. Automatic sheet fed paper bag machines enable the production of bags with handles that can hold varying weights, making them suitable for retail and shopping purposes.

-

Pharmaceutical and Cosmetic Packaging

Pharmaceutical and cosmetic products often require high-quality, sturdy packaging. These machines can produce high-strength bags with precise dimensions, ensuring the products are well-packaged and protected during transport.

-

Promotional and Gift Bags

Companies looking to create promotional or gift bags for events, conferences, or customer giveaways can utilize the machine to produce custom-designed paper bags with logos and messages to enhance brand visibility.

Conclusion

The Automatic Sheet Fed Paper Bag Machine is a game-changer in the packaging industry, combining high-speed production, precision, and versatility. By automating the paper bag manufacturing process, it helps businesses meet high demand efficiently while maintaining top-notch quality. As sustainability continues to drive the demand for eco-friendly packaging solutions, this machine presents a future-proof investment for companies seeking to align with global sustainability trends. Whether for retail, food, or promotional purposes, the machine provides an efficient and environmentally friendly solution for a wide range of packaging needs.