In today’s eco-conscious world, paper bags have become a symbol of sustainability, replacing single-use plastic bags in many industries. But have you ever wondered how these simple yet essential items are made? The answer lies in the fascinating world of paper bag machines. Let’s dive into the process of producing paper bags and explore the technology that makes it all possible.

The Basics of Paper Bag Production

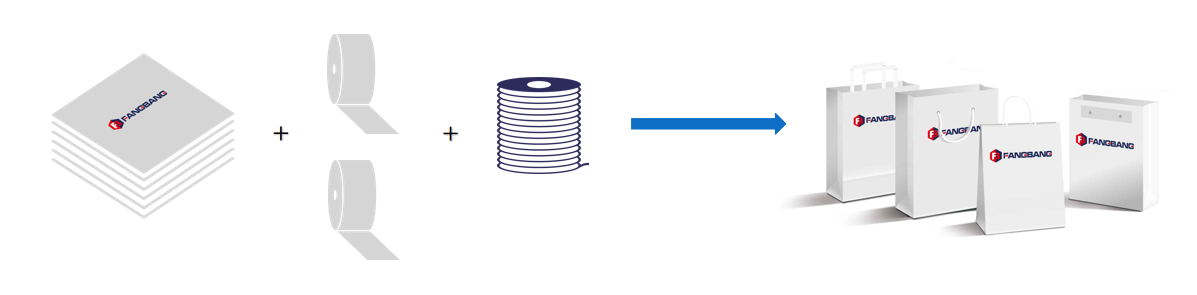

Producing paper bags is a multi-step process that transforms flat sheets of paper into sturdy, functional bags. While the process can be done manually, modern production relies heavily on paper bag making machines, which automate the entire workflow, ensuring efficiency, precision, and scalability.

Step 1: Choosing the Right Paper

The journey of a paper bag begins with selecting the appropriate paper material. Typically, kraft paper—a strong, durable, and recyclable material—is used. The paper can be virgin or recycled, depending on the desired strength and environmental considerations. The paper rolls are then loaded onto the paper bag machine, ready for processing.

Step 2: Printing and Design (Optional)

Before the bag takes shape, many manufacturers choose to print designs, logos, or branding onto the paper. This is done using high-quality printing units integrated into the paper bag machine. Advanced machines can handle multi-color printing, ensuring vibrant and eye-catching designs.

Step 3: Cutting and Folding

Once the paper is ready, the machine cuts it into the desired size and shape. The paper is then folded to form the basic structure of the bag. This step requires precision, as the folds determine the bag’s final shape and functionality. Modern paper bag machines use automated folding mechanisms to ensure consistency across thousands of bags.

Step 4: Gluing and Sealing

The next step involves gluing the edges to create the bag’s seams. The machine applies adhesive to the appropriate areas and presses the paper together to form a strong bond. This process is crucial for ensuring the bag can hold weight without tearing. Some machines also add reinforced bottoms for extra durability.

Step 5: Forming the Handles

Paper bags often come with handles for easy carrying. There are two main types of handles: flat handles (commonly found on shopping bags) and twisted handles (used in gift bags). The machine cuts, shapes, and attaches the handles securely, ensuring they can withstand the weight of the bag’s contents.

Step 6: Quality Control and Packaging

Before the bags are packaged, they undergo a quality control check. Modern paper bag machines are equipped with sensors and cameras to detect defects such as uneven folds, weak seams, or printing errors. Once approved, the bags are stacked, counted, and packaged for distribution.

The Role of Paper Bag Machines

The entire process of producing paper bags is made efficient and cost-effective by paper bag machines. These machines come in various types, including:

-

Flat handle paper bag machines: Ideal for shopping bags.

-

Twist handle paper bag machines: Perfect for gift bags.

-

Bottom pasting machines: Designed for bags with reinforced bottoms.

Advanced models are fully automated, requiring minimal human intervention. They can produce hundreds or even thousands of bags per hour, making them indispensable for large-scale production.

Why Choose Paper Bags?

Paper bags are not only eco-friendly but also versatile and customizable. They can be used in retail, food packaging, gift wrapping, and more. With the help of paper bag machines, businesses can meet the growing demand for sustainable packaging solutions while maintaining high standards of quality and efficiency.

Conclusion

The production of paper bags is a blend of art and technology, with paper bag machines playing a central role. From cutting and folding to gluing and handle attachment, these machines ensure that every bag is made to perfection. As the world continues to embrace sustainability, the humble paper bag—and the machines that produce it—will remain a vital part of our daily lives.

Whether you’re a business owner looking to invest in a paper bag machine or simply curious about how your shopping bag is made, understanding this process highlights the importance of innovation in creating a greener future.