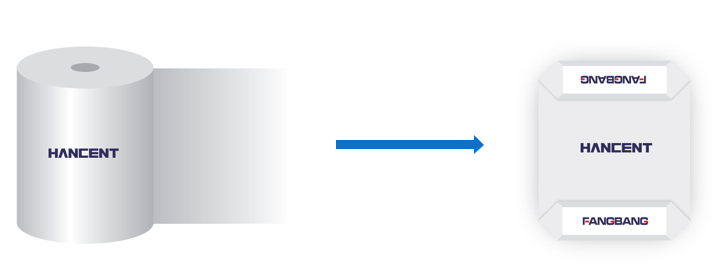

This machine produces square bottom plastic sacks with valves by taking double-sided coated polypropylene tube as raw material, which is the ideal equipment for rapid production of valve sacks. The machine has stable production speed ol1 15pcs/min,the creative negative pressure multi-step bag opening technology and vacuum bottom pasting transfer technology which make this machine be able to effectively reduce the cost of customers. Thanks to the excellent quality and fast sack-mak-ing speed, this machine is especially suitable for the mass production of packages for cement, chemical, grain and other powder and particle industries.

| TECHNICAL DATA | FB-S120 NEW |

| Sack Width | 400~620mm |

| Sack Length | 475-870mm |

| Bottom Size | 80-120mm |

| Bottom Center Distance | 375~750mm |

| Valve Sticker Width | 170~260mm |

| Valve Sticker Length | 80~200mm |

| Outside Patch Width | 80~120mm |

| Outside Patch Length | 300-500mm |

| Production Speed | 120pcs/min |

| Total Power | 150kw |

| Total Weight | Approx. 16000kg |

| Overall Dimension | L11000 xW7500x H2500mm |

This machine is an ideal machine for printing paper cup, carton, paper bag and so on.lt is controlled centrally by PLC s...

This machine is mainly used to produce various sized paper sacks by taking paper or paper+film tubes as raw materials, w...

This machine is mainly used to produce various sized sack tube (step-type and straight-type) by taking roll paper and PE...

Top Paper Bag Making Machine Manufacturers Leading the Sustainable Packaging RevolutionAs the global demand for eco-frie...

With the global enforcement of plastic bans and the deepening of circular economy policies, the paper bag manufacturing ...

In today’s fast-paced FMCG and retail industries, sustainable and efficient packaging solutions are no longer optional—t...

GET A QUOTE