In the diverse landscape of paper bag manufacturing, the sheet - fed paper bag machine holds a unique position. While roll - fed machines have their own set of advantages, sheet - fed models offer distinct features that make them indispensable for certain applications.

How It Operates

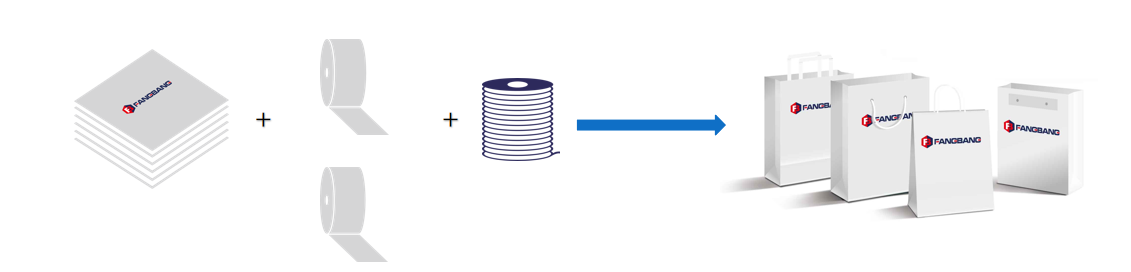

The sheet - fed paper bag machine starts with individual sheets of paper rather than a continuous roll. These pre - cut sheets are fed into the machine one by one. Once inside, the machine first aligns the sheet precisely. This initial alignment is crucial as it sets the foundation for the entire bag - making process.

Subsequently, the side seams are formed. Similar to roll - fed machines, this can involve folding and gluing or heat - sealing. However, the process on a sheet - fed machine may be more tailored to the specific dimensions and properties of the individual sheet. After the side seams are complete, the bottom of the bag is constructed. The machine folds the paper at the bottom in a specific pattern, ensuring a secure and well - formed base. This can be achieved through various techniques, such as using mechanical presses or specialized folding mechanisms.

Some sheet - fed machines are also equipped to add handles. The handles can be attached using glue, staples, or other fastening methods. This attachment process is carefully calibrated to ensure that the handles are firmly fixed and can withstand the weight of the items the bag will carry.

Advantages over Roll - Fed Machines

Precision in Small - Batch Production

One of the key advantages of sheet - fed paper bag machines is their ability to achieve high precision in small - batch production. Since each sheet is fed individually, it is easier to make adjustments for different bag designs within a single production run. For example, if a company needs to produce a small number of custom - sized paper bags for a special event or a limited - edition product line, a sheet - fed machine can handle this task with greater accuracy compared to a roll - fed machine, which may be more optimized for large - scale, uniform production.

Flexibility in Paper Selection

Sheet - fed machines offer more flexibility when it comes to the type of paper used. They can handle a wider range of paper thicknesses, textures, and even specialty papers. This is because the machine does not need to unwind a continuous roll, which can sometimes be a challenge with certain types of paper. For instance, thick, high - quality art papers or papers with unique coatings can be more easily processed on a sheet - fed machine. This flexibility allows for the creation of paper bags with a more luxurious or distinct look, which is often desired in the high - end retail or gift - wrapping industries.

Lower Initial Investment

For businesses with limited budgets or those just starting out in the paper bag production business, sheet - fed paper bag machines can be a more cost - effective option in terms of initial investment. Roll - fed machines, with their complex mechanisms for handling large rolls of paper, tend to be more expensive upfront. A sheet - fed machine, on the other hand, has a relatively simpler structure in some aspects, making it a more accessible choice for small - to - medium - sized enterprises looking to enter the paper bag manufacturing market.

Applications in Different Industries

High - End Retail

In high - end retail, where brand image and product presentation are of utmost importance, sheet - fed paper bag machines are often used. Luxury boutiques, for example, require paper bags that are not only well - made but also exude a sense of elegance. Sheet - fed machines can produce bags with precise folds, high - quality finishes, and custom - printed designs that perfectly match the brand's aesthetic. These bags are used to package expensive clothing, jewelry, and other luxury items, enhancing the overall shopping experience for the customer.

Artisanal and Handmade Goods

Artisanal food producers, such as small - batch chocolate makers or craft bakers, also benefit from sheet - fed paper bag machines. These businesses often want to package their products in a way that reflects the artisanal nature of their goods. The ability to use unique papers and create custom - sized bags with a personal touch makes sheet - fed machines an ideal choice. Additionally, for handmade gift items like hand - knitted scarves or hand - carved wooden utensils, the bags produced by sheet - fed machines can add an extra layer of charm and quality to the presentation.

Printing and Packaging Service Providers

Printing and packaging service providers that offer a wide range of custom packaging solutions rely on sheet - fed paper bag machines. They can use these machines to create prototypes quickly and efficiently. Since they often deal with a variety of client requests, the flexibility of the sheet - fed machine in handling different paper types and producing small batches is a significant advantage. This allows them to provide tailored packaging solutions for each client, whether it's a small local business or a large corporation with specific branding requirements.

In conclusion

the sheet - fed paper bag machine offers a set of unique features that make it a valuable asset in the paper bag manufacturing industry. Its precision, flexibility, and cost - effectiveness in certain scenarios make it a preferred choice for many businesses across different sectors. As technology continues to evolve, we can expect to see further improvements in sheet - fed machines, enabling them to meet even more diverse and demanding packaging needs.